Excel Hard 010 AR are used in heavy-duty industries for welding medium and heavy sections. Product is primarily used in applications where good wear resistance at elevated temperature is important along with considerable strength and toughness. Typical applications include chipper knives, conveyor bucket lips, shear blades, rock crusher, rock drills, hot work dies, crusher hammer. Specially designed for adamite roller’s build up.

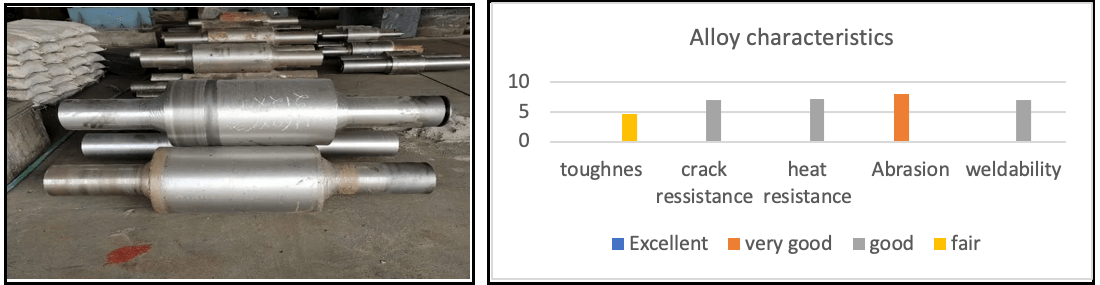

Hard facing electrode operates well on all condition positions. The deposited weld metal has exceptional abrasion, heat, and wear resistance. Evenly rippled, porosity free weld deposit permit heavy buildup without danger of cracking. This is specially designed for adamite rollers.

Ensure that the electrode is perfectly dried before use. In case of moisture pick up, redry the electrodes at 200°C for one hour before use. Clean the weld area, remove fatigue material by machining and free it from all contaminations. Hold a short arc length with a short arc. Preheat the job if it contains C% higher than 0.4%.

| SIZE (mm) | AMPERAGE |

| 4.00 | 130 – 170 |

| 3.15 | 90 – 120 |

1. Current: AC/DC + 2. Hardness: 50 – 55 HRC