Extra low carbon stainless steel electrode for joining and surfacing on stabilized chemically resistant steels 202, 302, 304, 304L, 305, 308, 308L.

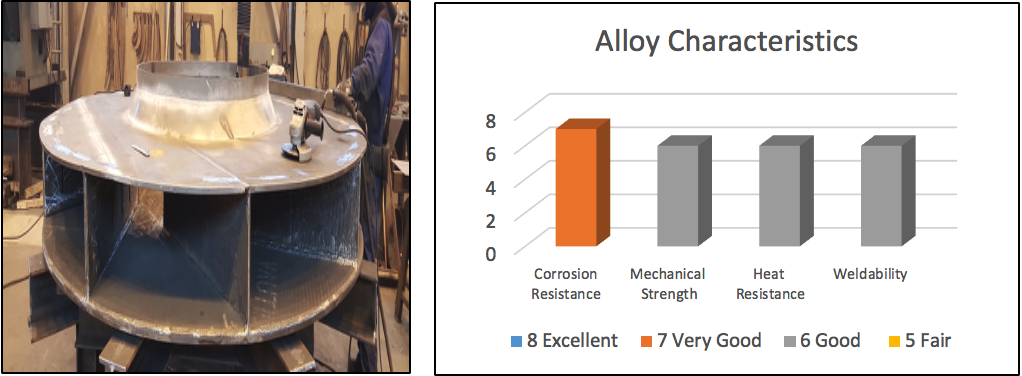

All-purpose electrode with high corrosion and heat resistance for metallic arc welding 18/8 and 19/9 stainless steel, types 301, 302, 304, 304L, 305, 306, 308 and 347, in all positions. Especially recommended for joining extra low carbon grades to minimize carbide precipitation and eliminate intergranular corrosion. Applicable for dairy, chemical and distillery equipment. Ideal as a protective overlay on steel, where medium hardness and complete corrosion resistance are required. Excellent resistance to impact, heat and scaling.

Clean weld area. Thickness up to 10 gauge can be square butt welded. Heavier sections should be beveled to a 60°C angle. Tack at short intervals to maintain alignment. Hold electrode at 15°C angle in the direction of travel. Maintain a short arc. Stringer beads are preferable. Clean slag between passes. Use a number of light beads. Use skip or step back technique. Use electrode positive with DC machine.

| SIZE (mm) | AMPERAGE |

| 5.00 | 135 – 185 |

| 4.00 | 85 – 140 |

| 3.15 | 55 - 100 |

1. Current: AC/DC + 2. Tensile Strength > 85,000 psi 3. Elongation > 35%