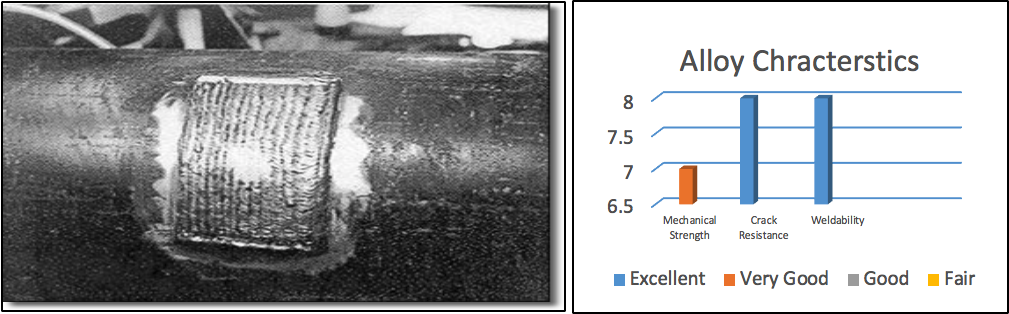

Versatile Nickle base alloy for nuclear fabrication of Nickle base materials. 9% Ni steel used for cryogenic service up to -196⁰C. Dissimilar joining of austenitic steel to ferritic steel.

For all types of heat treatable steels, difficult to weld steel. Weld joints are highly resistant to thermal cycling. Gives high degree of safety in welding different grade of Ni bearing alloys.

Make 90⁰ V groove, maintain short arc gap, remove slag after every bead for multi-pass build ups. Slow cool the weld deposit. Follow weaving for 2 X . Clean the slag between passes.

| SIZE (mm) | AMPERAGE |

| 4.00 | 160 – 200 |

| 3.15 | 130-170 |

| 2.50 | 80-90 |

1. Current: AC/DC + 2. Tensile Strength > 88,000 psi 3. Elongation > 35%