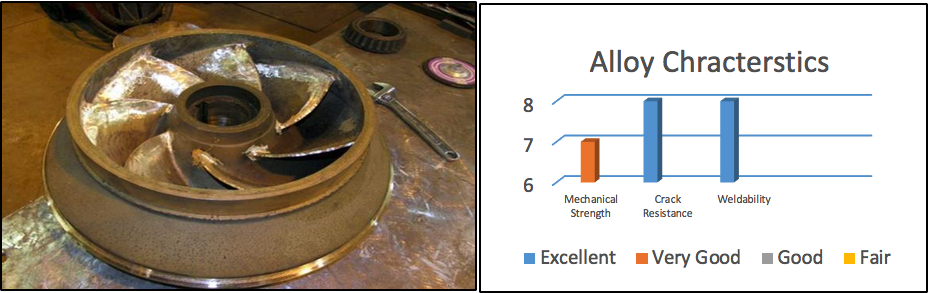

Special high alloy low heat input electrode for joining high-alloy steels & dissimilar joints between carbon steel/low alloy steel to high alloy steels. Applications include welding of furnace parts, static collars, journal areas, buckets.

Universal electrode for joining & overlaying all types of steel for high strength with high heat & corrosion resistance. Exceptionally easy to handle, either with a short arc or as a contact electrode. Special Frigid-Arc coating permits lowest operating amperages, eliminating distortion and warping.

Clean weld area. Bevel heavy sections 60°-90°. Use a short arc or contact technique. Stringer beads are recommended followed by stress relieving peening on crack sensitive applications. Intermittent welding may be used, to prevent local heat build-up. Remove slag between multiple passes.

| SIZE (mm) | AMPERAGE |

| 5.00 | 165 – 190 |

| 4.00 | 140 – 165 |

| 3.15 | 105 – 130 |

| 2.5 | 65 - 75 |

1. Current: AC/DC + 2. Tensile Strength: 85,000 psi 3. Elongation: 30%