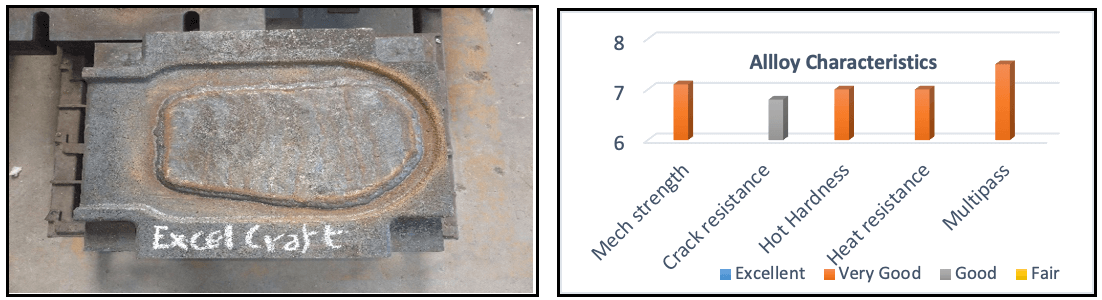

Designed for its high hardness & high temperature resistance well suited for surfacing on machine components and tools exposed to severe impact, compressive load conditions and abrasion at operating temperature up to 400°C such as tongs slides hot shear blades extrusion pistons, dies strippers steel punching tools. Specially made for hammer dies.

Build ups, worn out or cracked hot forging dies. Specially designed for repairing hammer dies. It is mandatory to use proper preheating & post heating procedure recommended for welding when used for DIN 1.2714 or DIN material of equal grade.

Clean metal surfaces. Use “Excel Gouge” to remove damaged metal. Pre-heat work piece up to 400°C. Hold electrode as vertical as possible and with a short arc. Allow work piece to cool down slowly. Re-dry electrodes for 2hr at 250°C prior to use

| SIZE (mm) | AMPERAGE |

| 5.00 | 220 - 250 |

| 4.00 | 130 - 170 |

| 3.15 | 90 - 130 |

1. Current: AC/DC + 2. Hardness: 45-50 HRC