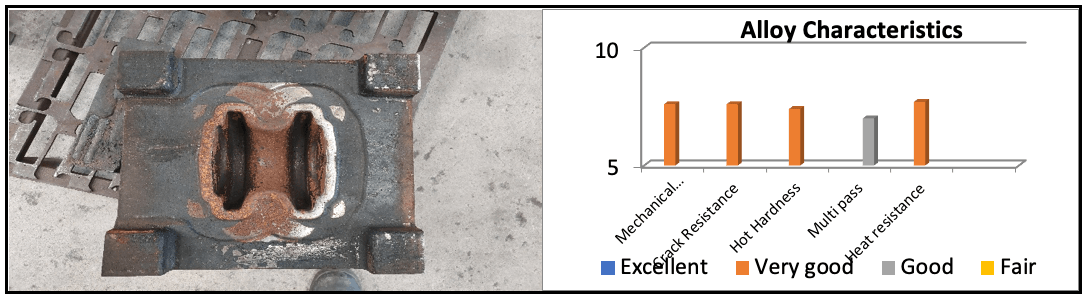

Basic coated electrode for high temperature resistant surfacing on hot work steels exposed to impact, compression, and abrasion. This electrode has excellent welding characteristics. Good bead appearance and very easy slag removal. Heat resistance up to 450°C.

Build ups, worn out or cracked hot forging dies. Suitable for repairing hot forging dies H-13 material. It is mandatory to use proper preheating & Post heating procedure recommended for welding when used tool steel of any type.

Clean welding area properly. Pre-heat the work piece up to 400°C. Hold the electrode as vertical as possible and with a short arc. Allow the work piece to cool down slowly. Re-dry the electrode for 2 hr at 300°C prior to use.

| SIZE (mm) | AMPERAGE |

| 5.00 | 190 - 240 |

| 4.00 | 120 - 170 |

| 3.15 | 90 - 120 |

1. Current: AC/DC + 2. Hardness: 38-42 HRC