Basic coated electrode for temperature resistant surfacing exposed to compression and abrasion. Deposit is machinable. Application includes rollers, Idlers, flood welding on DIN 2714 material.

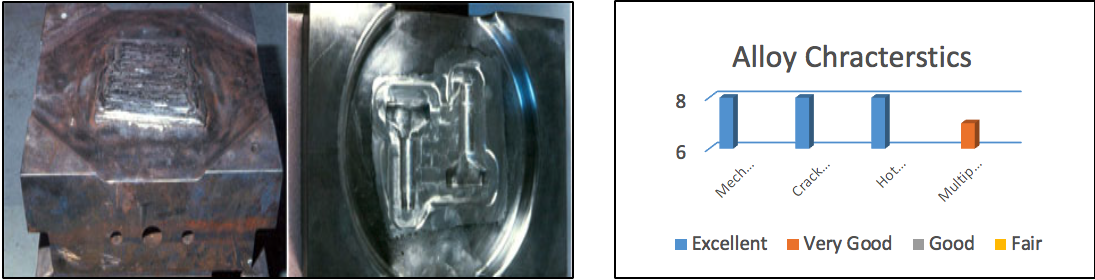

Build ups, worn out or cracked hot forging dies. Buffer layer of Excel Forge 011 is recommended.. Suitable for repairing hot forging dies, H-13 material. It is mandatory to use proper preheating & post heating procedure recommended for welding when used for tool steel of any type.

Clean weld area properly. Worn out weld material should be removed by air arc gouging. Carry out the preheating as recommended for the base material. For heavy section preheat up to 250-300⁰C. For stress relieving 550⁰C – 600⁰C and soaking @ 1 Hr./inch of block thickness.

| SIZE (mm) | AMPERAGE |

| 5.00 | 180 - 200 |

| 4.00 | 145 - 160 |

| 3.15 | 110 - 130 |

1. Current: AC/DC + 2. Hardness: 45-50 HRC