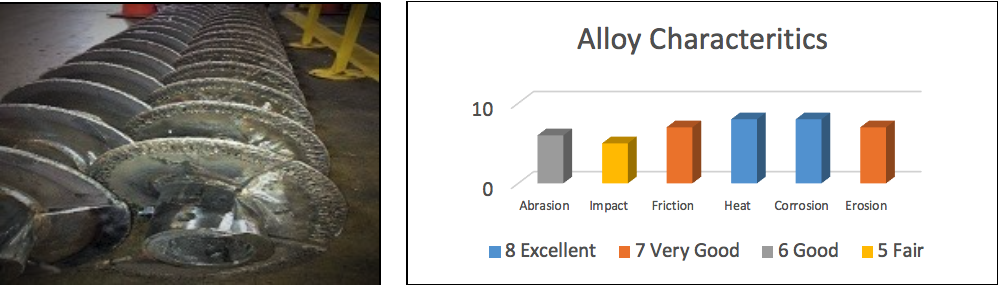

Contact type high chromium carbide deposit alloy electrode for anti-wear surfacing on parts such as screw conveyors, scrapers, fiberizer hammers, cane cutting knives, needle bearing areas, grader blades.

Good compressive strength and superior weldability. Frigid arc coating of this low Amp “Excel Gouge” aids in producing a fast deposition rate. For use where a combination of hardness and toughness is desired on carbon and alloy steels, manganese steel and cast iron. For frictional and abrasive

Clean metal surfaces. Use ”Excel Gouge” to remove damaged metal. A slight preheat is recommended for alloy steels and cast iron. Use either AC or DC reverse polarity. Maintain a medium arc; incline the electrode at an angle 75° from horizontal in direction of travel. Use modified to wide weaving technique. Remove slag after every pass.

| SIZE (mm) | AMPERAGE |

| 5.00 | 180 – 200 |

| 4.00 | 145 – 160 |

| 3.15 | 110 - 130 |

1. Current: AC/DC + 2. Hardness: 55 – 60 HRC