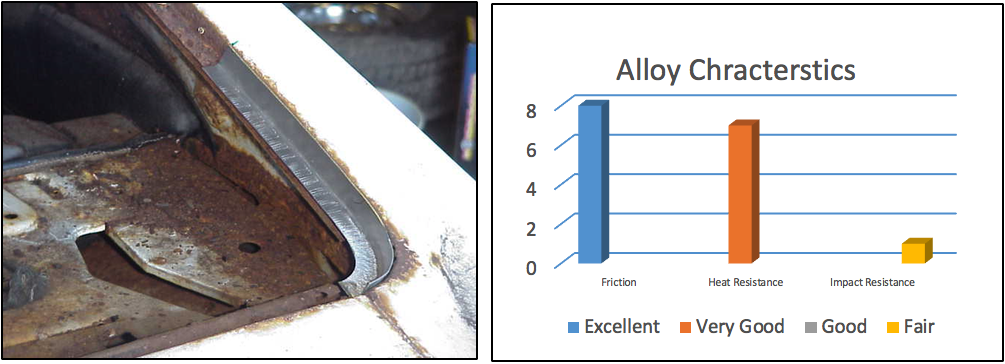

Manual electrode giving high speed steel –Mo electrode for anti-wear surfacing on the parts subjected to friction, Impact and heat up to 550⁰C. Application includes cutting tools such as shear blades, Milling tool, HSS tools, Broaches & piercing dies.

Provides maximum hardness at edge at high temperature. Most suitable where cutting, piercing & shaving qualities are required. Ideal for build ups on composite blanking, punching dies.

Remove all damaged and fatigued weld metal and clean weld area. Preheat larger sections up to 200- 450⁰C. On DC use reverse polarity. Use 50-75 mm at a time to avoid heat concentration. Chip off slag between passes. Use Excel Bond 086 as a buffer layer.

| SIZE (mm) | AMPERAGE |

| 400 | 160 – 200 |

| 3.15 | 130 – 160 |

| 2.50 | 75-90 |

1. Hardness: 58-62 HRC